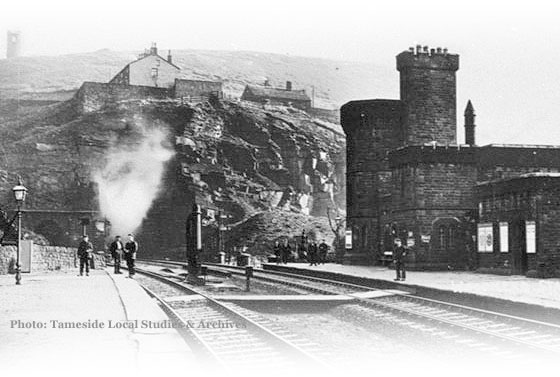

Wellington A Purdon recounts the construction of... Woodhead's first tunnel

Wellington A Purdon recounts the construction of… Woodhead’s first tunnel

Driving the headings/excavation & lining

Driving the headings

The open excavation of the western face of the tunnel was early cleared out and the driving of the drifts was commenced at the same time as the shafts sinking, 30th September 1839. But the excavation at the eastern face was a more tedious operation and a shaft 21 yards deep was soon sunk with a view to admit the driving to proceed. Before starting however, the water began to rise in the bottom and, no means being prepared to lift it out, the driving here was suspended until the excavation was cleared out in September 1840. The driving from the eastern and western faces then proceeded uninterruptedly until met by the headings driven from the shafts.

The dates at which the sinking of the various shafts reached the bottom have been stated. After this period no time was lost in commencing to drive the horizontal driftways in every instance. The dates at which the headings met the driving in opposite directions, together with the distance of the points of junction from each shaft, are as follow –

| Between | And | Date of meeting | Distance |

| West face | No. 1 shaft | 24th March 1843 | 94 yards from No. 1 shaft |

| No. 1 shaft | No. 2 shaft | 17th January 1845 | 203 yards from No. 2 shaft |

| No. 2 shaft | No. 3 shaft | 6th March 1845 | 450 yards from No. 3 shaft |

| No. 3 shaft | No. 4 shaft | 30th January 1843 | 405 yards from No. 4 shaft |

| No. 4 shaft | No. 5 shaft | 18th December 1842 | 396 yards from No. 5 shaft |

| No. 5 shaft | East face | 17th September 1842 | 986 yards from east face |

It would be tedious to describe the various casualties which occasioned more or less delay in the course of driving each heading. It may be sufficient to say that, through the hardest material met with, 3 yards a week could be driven and, in the softer shales, 13 yards a week. The rate through the various measures may be said to be 7 yards a week.

It is to be observed that the cost of driving through hard or soft ground is not widely different as it was necessary to apply settings of timber to support the latter – the price of which and the fixing brought up the cost as high as that of the solid rock. There were of course rails laid down in the bottom heading for removing the excavation and the material of the top heading was put down through the connecting shafts into the wagons; sidings or passing places being made occasionally for the wagons as the driving proceeded.

The communication between the tunnel and the point vertically under the shafts was effected by lurries worked on lateral rails at a lower level. This was found more practicable than turntables which are liable to choke in such situations.

Excavation & lining

The widening excavation was commenced in March 1843 at the eastern face and at the bottom of shafts 3, 4 and 5, and before May in the same year at the western face and No.1 shaft. At this time, No.2 shaft had not reached the bottom, and 257 lineal yards of driftways towards No.3 and 748 yards towards No.1 – in all 995 yards – remained to be driven. The remainder of the tunnel, viz – 4,300 yards was perforated by a double driftway in the manner described.

The course pursued was to open a length at each shaft and also at the two entrances of the tunnel; where the ground was not sufficiently strong to stand, a lining of masonry was quickly inserted. Two extra faces were shortly opened in each of the end stretches, ahead of the excavations carried on from the entrances. When the shaft lengths were properly finished, two faces of work naturally opened in opposite directions. The material was drawn out at the entrances from all the faces of work in the end stretches; and that from the other faces was drawn up the shafts, the capacity of which, and that of the lifting appliances, set the limit to the rate of progress in the shaft stretches. Otherwise, a limited number of fresh faces of operation might have been opened, further in the driftways, as was the case towards the close when the reach near No.2 shaft came to be pressed, after the water was mastered by a second engine, and the remainder of the tunnel was free on both sides to admit of the excavated material to be taken away.

The total quantity of excavation removed from the tunnel was 227,685 cubic yards, (43 cubic yards per yard forward) of which 109,390 cubic yards were drawn up the shafts and the remainder out at the ends.

The different qualities of the various strata did not admit of a uniform practice at each face. In places where no lining was required, the top driftway was widened and the part between the upper and lower drifts knocked out. The haunch of the arching was then formed and the excavation got down and the sides trimmed in lengths of 10 or 20 yards at a time. Where beds were so friable as to require supporting to admit the lining, the usual course was pursued of opening in at the crown and inserting, down on each side, the requisite sills, bars, props etc. By resorting to lengths so short as 9 feet at a time, security was insured. Between these extreme qualities of strata, there were various degrees, requiring more or less of such appliances.

It required well considered arrangements to carry on all those faces of operation together as the getting in of the requisite stone, mortar and timber etc in so limited a space, as well as removing the excavated material.

There were arches left on the north side, under the springing level, 10 feet span and 6 feet deep, every 200 yards of the length, to facilitate the construction of the second tunnel.

The tunnel was lined throughout except about 300 yards. The thickness of the lining was generally 18 inches; but in weak ground at certain places it was frequently increased to 3 feet and sometimes more. The character of the masonry was blocking course for the side walls, made with hammer-dressed sandstone got in quarries about the hill and some in the tunnel. The arching was of flat-bedded reap stones of the same description, worked in as bricks, in 6-inch courses, and bonded together as the rings overtook. The entire was set in common hydraulic mortar and cost about 16 shillings per cubic yard.

It would exceed the object of this paper to extend these remarks much farther.

The cost of the double driftway was about £7 10s per lineal yard, including the air holes that connected them at intervals. The sinking of the shafts cost £48 per yard, but the engines and pumping apparatus were to the good for the horizontal work afterwards. The completed tunnel cost £38 a yard forward, or £201,210.

It was opened for public traffic on 23rd December 1845 and it may be said to have occupied six years in constructing.

Driving the headings/excavation & lining