Four bores through Standedge: Noteworthy LMS tunnels

- Source: LMS Railway Magazine

- Published: March 1925

Four bores through Standedge: Noteworthy LMS tunnels

The Great Western Company’s Severn Tunnel, 4 miles 636 yards in length, is the longest tunnel in Great Britain. Next to it comes the LMS Totley Tunnel, 3 miles 950 yards long. The third longest tunnel, on the LMS Manchester-Leeds line, is now to be described.

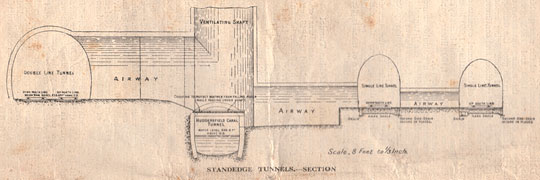

The Standedge double line tunnel is 3 miles 64 yards in length and there are three other tunnels running parallel to it. The first of the four to be constructed, and incidentally the longest, was…

The canal tunnel

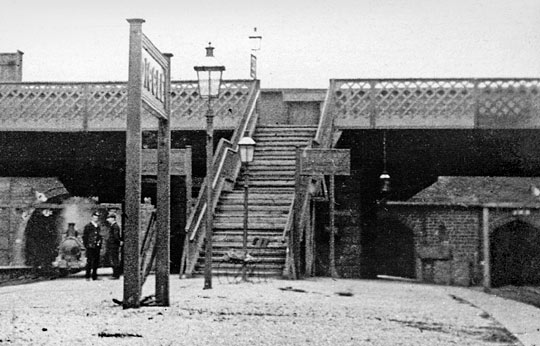

Photo:

Saddleworth Museum Archives – A Community Resource

This passes under the mountainous district known as Standedge. It is the summit level of the Huddersfield Narrow Canal and the three Acts of Parliament under which it was constructed are dated 1794, 1800 and 1806. The Huddersfield & Manchester Railway Company acquired it, together with the Huddersfield Broad Canal at Huddersfield, under the Act of 1845. Both the railway and canals were vested in the L&NWR in 1847.

The length of the whole summit level is 4 miles and the height above OD 648.6 feet which is greater than that of any other canal in the country. It is straight throughout.

The canal rises 438 feet 10 inches to the summit level from Huddersfield to Marsden by 42 locks in eight miles and falls through a series of 32 locks 338 feet 1½ inches from Marsden to Ashton in less than nine miles.

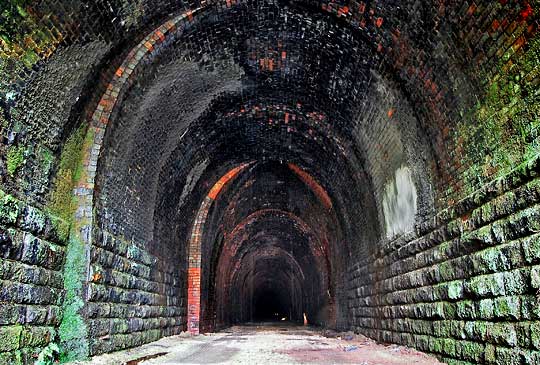

The original construction of the canal tunnel, which had a length of 3 miles 135 yards, was partly of stone arch with side walls and partly rock cutting. In places the rock beds are horizontal and much broken up, in consequence of which ‘falls’ of rock occasionally take place.

The work was commenced in 1794 and completed in 1811, at a cost of £271,000. There is no towpath through the tunnel and the boats are propelled through by boatmen – or ‘leggers’ as they are called – from the roof or sides, the operation occupying 1½ to four hours, according to the weight of the cargo and the number of men engaged in the work. The boat horses and attendants travel by road over the tunnel.

There are four ‘wides’ or passing places for boats in the tunnel, viz Brunnclough Wide, Whitehorse Wide, Old Judy Wide and Redbrook Wide at distances of 0.8, 1.1, 1.5 and 1.7 miles respectively from the Diggle end.

Practically the whole water supply from the reservoirs situated on the top of Standedge is brought down the lockages on each side of the summit level. The minimum height above water level is 6 feet 8 inches, width 7 feet 3 inches, and average depth of waterway is 4 feet.

During the construction of the new double-line tunnel between 1890 and 1894, great damage was done by the mining operations to the canal tunnel. To make good the damage, a considerable length of brick flying arches (with side walls where required) and continuous arching were built.

Photo: Phill Davison

The present lining of the tunnel consists of 2,300 linear yards of rock cutting, 1,060 linear yards stone lining, 870 linear yards brick flying arches (new work) and 1,130 linear yards continuous arching (new work).

In construction of the new double tunnel, about 32 yards of the original canal tunnel at the Diggle end was removed and the waterway covered over with steel girders and floor plates for a length of about 275 yards.

Of the ventilation shafts for the tunnels, seven are situated directly over the canal tunnel and one over a side passage or waterway, but a detailed description of these is given under the head of ‘ventilation’.

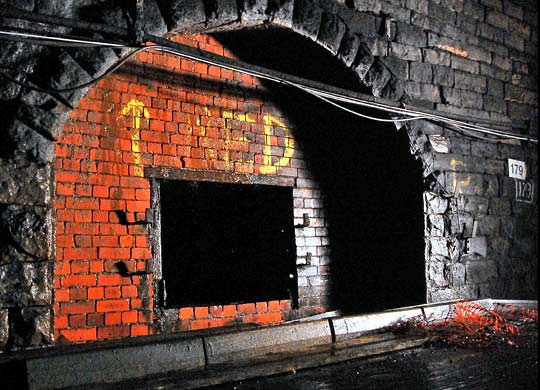

Down South single-line tunnel

The construction of this tunnel was commenced in 1845 and completed in 1848 at a cost of £201,608. Its length is 3 miles 62 yards and the contractor was Mr Nicholson. It has an average width of 14 feet 6 inches at rail level, height above rail level being 17 feet 6 inches and its original construction was a stone arch with side walls. The formation through which it passes is the shales and rocks of the coal measures in which there are some ‘main faults’ and several subsidiary ones. Where these latter occur, the shale and rocks are very much distorted and shattered.

The original contour of the tunnel is in many places distorted, the crown of the arch being forced up. On opening out at these places, cavities were found over the crown and the rock very much shattered and drawn. Behind the side walls the shale was very compact. Portions were taken down and rebuilt. The stone arch at the crown varied from 10-22 inches thick (in three rings) and the side walls 22-27 inches, the face work being 10 inches thick. A defective length of 117 yards was rebuilt in 1894 at an actual cost of £4,589, or £39 4s per linear yard.

A further length of 73 yards was rebuilt in 1916-18; this latter work cost £67 per linear yard forward. In 1912-13, similar work was done at £48 per linear yard forward over a length of 17 yards and another length of 13 yards at a cost of £52 per linear yard forward. In other places the arch ring has been repaired and cavities over the crown hand-packed. The height above rail level in the reconstructed portions is 17 feet 6 inches.

The rebuilding carried out in 1916 to 1918 is about 650 yards from the Marsden end of the tunnel and was necessitated by the damage done by the mining operations in the construction of the new double tunnel between 1890 and 1904. Adjoining this place, the stone arching in the canal tunnel was found to be very much damaged and crushed, and a length of 33 yards was taken down and rebuilt.

A continuous deluge pours down it.

Photos: Phill Davison

In the length of the new double tunnel also adjoining, defective work was found, and the cavities above the crown were hand-packed and defective arching taken out and rebuilt.

In this tunnel, at a distance of about 1,075 yards from the Marsden end, 16 inch square longitudinal timbers were fixed below rail level and alongside the side walls for a length of 150 feet with 25 15-inch square wooden struts between, but below sleeper level. This work was done about 1881. The stone arching in the corresponding length of the canal tunnel was rebuilt about the year 1897.

In the new double line tunnel adjoining, which is inverted, the arch had to be repaired and the cavities found above the crown hand-packed about 1900. Both side walls of the single-line tunnel at this place have been thrust forward towards the centre, and there are also signs that the timbers and rails have been forced upwards. Iron rail centres have now been fixed in this place.

There are 13 cross-adits from this tunnel to the canal tunnel, and it is straight for its whole length.

In this tunnel, an amount of £10,100 has been spent on relining and other important renewals between the years of 1894 and 1912.

Up South single-line tunnel

Photos: Phill Davison

The construction was commenced in 1868, and completed in 1870, at a cost of £121,500. Its length is 3 miles 62 yards, and is straight throughout. The contractor was Mr Nelson. It has an average width of 14 feet at rail level, with an average height of 15 feet 6 inches above rail level. The repairs carried out to this tunnel since 1871 are not as extensive as those done in the Down single-line tunnel. However, in 1894, 42 yards of the tunnel was rebuilt – the estimated cost was £1,122 pounds, being equal to £26 14s per lineal yard forward. In 1920, a further 10 yards was similarly dealt with – the estimated cost was £700, being equal to £70 per lineal yard forward. The actual cost was £1,298.

The construction of this tunnel was brickwork in mortar made with blue lias lime, with the brickwork in Portland cement in places. The section generally adopted was side walls 1 foot 6 inches thick, arch ring 14 inches thick. Additional thicknesses were built in places as required, the side walls being 2 feet 3 inches thick, and the arch rings 1 foot 6 inches. The width between the side walls was 15 feet, though this has now contracted very much in places.

Refuges were plentiful – good news when trains were approaching.

Photos: Phill Davison

Twenty-one large working headings were used for driving the Up single-line tunnel. These commence in the canal tunnel at varying levels, and run in form of an arch to the old railway tunnel. The floor at the side of the old railway tunnel (now the Down single-line tunnel) is about 6 feet or 7 feet below the rails in it. Some of these archways are open direct to the old tunnel, some are walled up with doorways 6 feet deep, 2 feet 6 inches wide, and some are walled up completely. From these arches there run culverts underneath the old tunnel, used for draining, and in some cases for ventilating it. The culverts generally terminate in arched chambers between the railway tunnels, which stop a few feet short of the new railway tunnel. In five cases these chambers communicate with the new tunnel through cast iron grids at canal side of rails. There are 35 air headings from the old railway tunnel to the canal tunnel, most of which are driven through the rock, varying in shape and size, and having a large arched entrances. When in working order, they are such as to admit of walking from the railway tunnel to the canal tunnel. About one-third of these headings have been stopped up, either by tipping or walling up, or by both means.

Photo:

Saddleworth Museum Archives – A Community Resource

Thirty-one cross headings, with arches about 4 feet 6 inches deep by 3 feet wide, form ordinary means of communication between old and new railway tunnels.

Of the five shafts, four are directly over the canal and one, the Redbrook Down Cast shaft, is between the railway and canal tunnels. Four also are in direct communication with the old railway tunnel by large headings or grids.

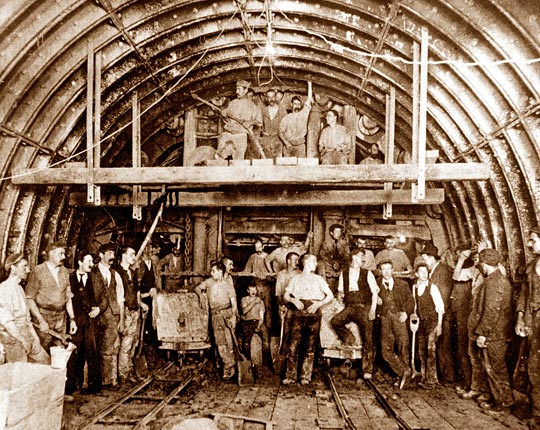

Double-line tunnel

Photo: Phill Davison

This is the most recently constructed tunnel. It was commenced in 1890 and completed in 1894. The work was begun by the railway company, but completed by contractors. Its length is 3 miles 64 yards, and constructed of brick arch and side walls. The formation passed through is similar to that of the three previous tunnels. At various places concrete inverts were provided.

Since 1894 signs of bricks being crushed in the arch were noticed in several places, and on making trial holes in the crown, defective work was brought to light. Many cavities were found, with the crown bars left in. The existence of 9-inch dry brick midfeathers apparently showed that the cavities had been well packed but on further investigation more cavities were found beyond the midfeathers. These cavities subsequently were solidly hand-packed and the arches taken down and rebuilt when necessary. The cost of these repairs was about £1,600.

Rail level Standedge double-line tunnel is 658.89 feet above OD.

The new shafts at Brunn Clough, Redbrook and Flint Pit were constructed in connection with the new double-line tunnel, and the remainder are the original shafts. All, with the exception of Redbrook Down Cast shaft, are over the canal tunnel.

Ventilation of the tunnels

| Name of shaft (currently existing) | Mileage (miles/yds) | Diameter (feet/in) | Approx height above rails (ft) | Approx height above O.D. (ft) |

| Diggle face of tunnel | 15m240 | – | – | – |

| Cote pit | 15m1097 | 10ft0 | 216 | 876 |

| Brunn Clough | 15m1660 | 20ft0 | 457 | 1,117 |

| Redbrook (new) | 16m1324 | 15ft0 | 512 | 1,172 |

| Redbrook (Up Cast) | 16m1440 | 7ft3 | 474 | 1,134 |

| Redbrook (Down Cast) | 16m1454 | 9ft0 | 479 | 1,139 |

| Flint pit (old) | 17m475 | 10ft0 | 454 | 1,124 |

| Flint pit (new) | 17m613 | 15ft0 | 497 | 1,156 |

| Pule | 17m1532 | 12ft0 | 460 | 1,120 |

| Marsden face of tunnel | 18m303 | – | – | – |

The railway tunnels are ventilated naturally by six of the shafts by means of cross adits of varying sizes. The two shafts at Redbrook – Down Cast and Up Cast – are the only ones in which any attempt has been made to artificially create a circulation of air.

In Redbrook Down Cast shaft, the air is brought down by a means of water sprays. Water near the surface of the ground is collected into a channel by means of a special arrangement, and spreads so as to fall in spray form down the shaft. This causes further air to follow, and the Up Cast shaft being only about 14 yards away, the constant circulation of fresh air is provided.

Photo: Phill Davison

The volume of water and air can be regulated in and out of the single-line tunnel at these shafts by means of gratings and doors, which control the air through various passageways under the lines.

The doorways over the open grating to the ventilating subway in the Down single-line tunnel are raised or lowered by chains by the platelayers when they require to ventilate the tunnel. By raising the doors the current of air coming down the Redbrook Down Cast shaft passes through the subway and thence upwards through the open grating at about sleeper level. This disperses the smoke in the tunnel in both directions.

If the Up single-line tunnel is required to be cleared, the doors are left down and the adjoining shuttles raised. This allows the current of air to pass further along the subway, thence through the open grating in that tunnel. When no ventilation is required the doors and shuttles are left down.

More Information

| Subterranea Standedge | Phill Davison’s remarkable exploration of a hidden world. |

| Wikipedia | History of the tunnels |