Latchford Viaduct

Latchford Viaduct

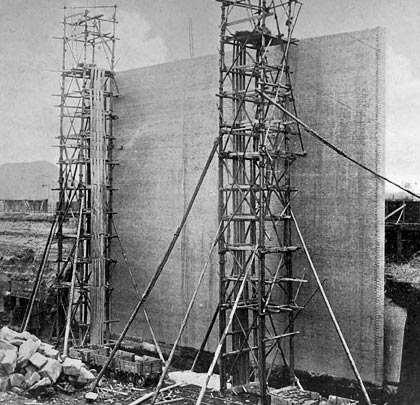

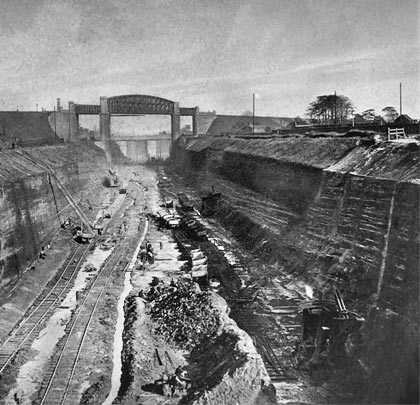

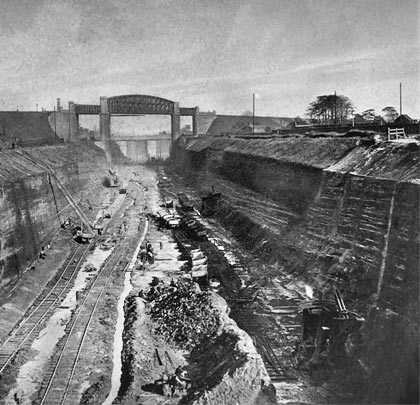

At the peak of its six-year construction period, the Manchester Ship Canal occupied 17,000 navvies as they excavated more than 54 million cubic yards of material. The project, costing the equivalent of £1.7 billion today, benefited from 180 locomotives, 124 steam cranes and 97 steam excavators. It remains the world’s eighth-longest ship canal, is only slightly shorter than the Panama Canal and has a depth of 28 feet, equalling that of the Suez Canal. My any measure, it is a truly substantial engineering feat.

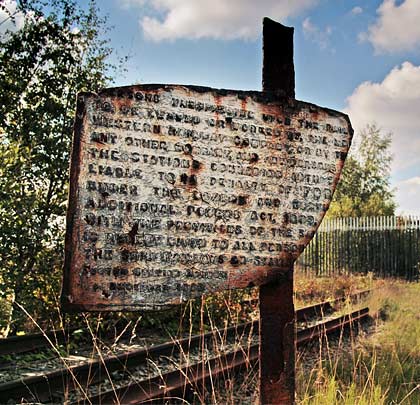

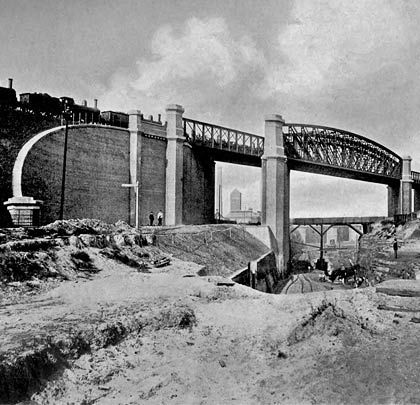

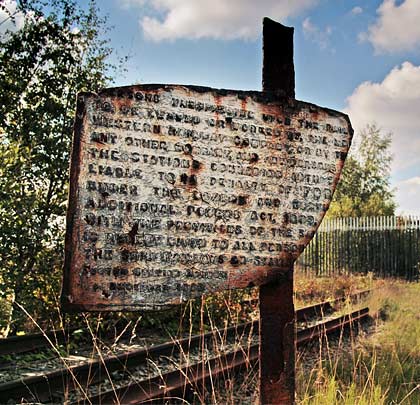

Cutting it demanded the rerouting of three railways to cross the water on viaducts at a high level. Deviation of the Stockport-Warrington line at Latchford was carried out by the London & North Western Railway, but this undertaking proved a cause of considerable tension with the canal company. Although ready for use in 1892 and approved by the Board of Trade, the L&NWR refused to use the new route for passenger traffic until it had received – in full – the compensation agreed by an arbiter; this meant that the original alignment held up progress with the waterway’s excavation. The impasse was eventually broken by a transfer of money, allowing the first passenger train to climb up the 1:135 approach embankment to cross Latchford Viaduct at 07:30pm on Sunday 9th July 1893. Goods traffic had been using it for five months.

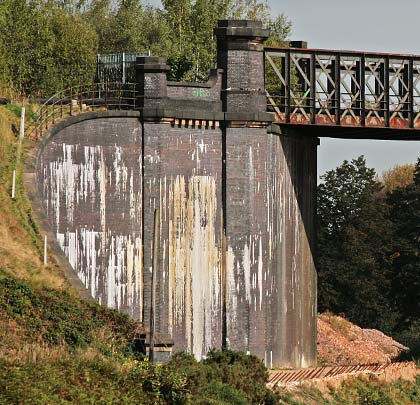

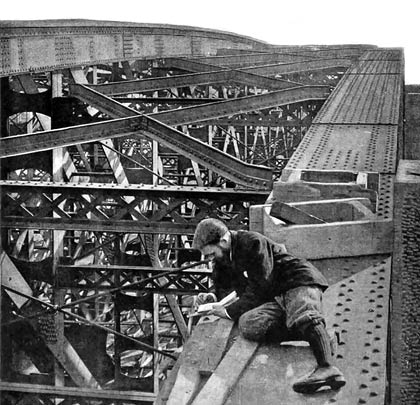

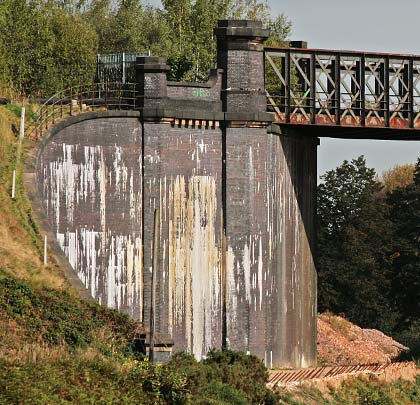

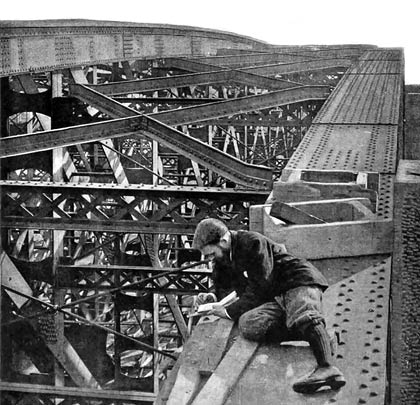

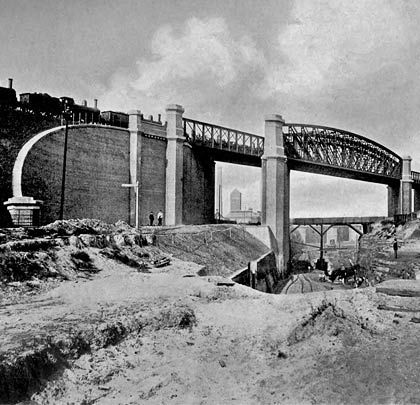

Built by Arrol from wrought iron, the main span consists of three girders, 280 feet in length and 18 feet apart. Each one extends 38 feet 3 inches beyond its neighbour due to the 66 degree skew perpendicular to the canal. Hog-backed, the girders vary between 23 feet in height at either end to 34 feet at the centre and comprise a double system of bracing with vertical struts and inclined ties. The cross girders, spaced 8 feet 1½ inches from centre to centre, are 13 inches deep and have a curved lower flange. Attachment to the main girders’ lower booms is by riveting.

Each of the side spans comprises two girders 98 feet in length and 14 feet high, spaced 34 feet 6 inches apart; they overlap for a distance of 21 feet 6 inches. The falling gradient and curvature necessitated heavier cross girders on the west side, with a corresponding increase in the main girders’ strength.

The bearings of each girder are fixed at one end and free at the other, pin joints being placed at each end. The bed plates and saddles are all made of cast steel. The upper saddle measures 3 feet by 8 feet 5 inches and is bolted to the underside of the lower boom by sixteen bolts. The steel pin is 5 inches in diameter and 3 feet 2 inches in length. The lower saddle is 2 inches shorter but stands rather higher. At the free end, the six rockers are of Siemens-Martin mild steel, set in frames and secured by a ⅞ inch set screw at each end.

The abutments and piers are constructed from rubble sandstone and red brick, faced with blue bricks; the string courses and capstones are masonry.

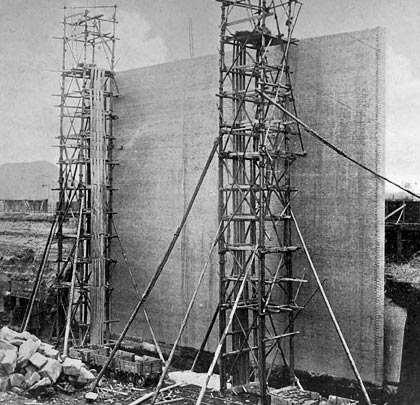

Overall, the structure weighs 1,220 tons and provides a clear headway of 77 feet 1¼ inches above water level. Used in its construction were 6,554 cubic yards of concrete, 28,268 cubic yards of masonry and brickwork, as well as 13,145 cubic feet of ashlar.

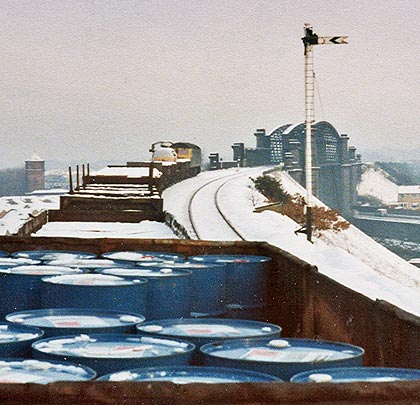

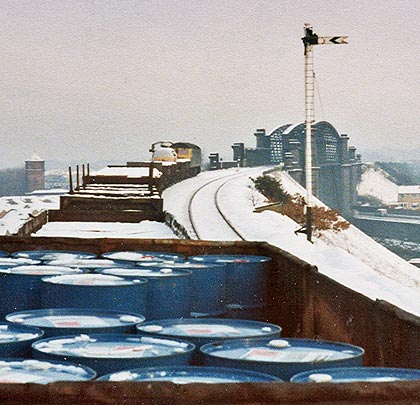

The line over the viaduct saw its last passenger services in 1962 but freight continued to be carried until July 1985. Closure was due in no small part to the viaduct’s poor condition and the unsustainable cost of refurbishing it.

(Ingy the Wingy’s photo is used under this Creative Commons licence.)