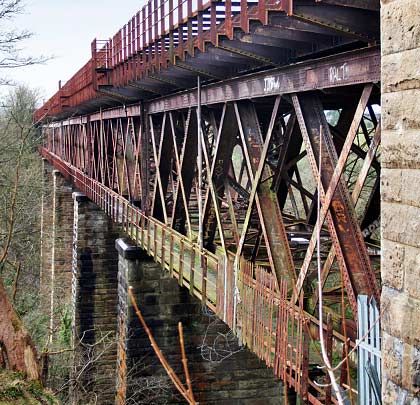

Larkhall Viaduct

Larkhall Viaduct

The Caledonian Railway completed extensions to its mid-Lanarkshire and Ayrshire system in 1905 under the powers of Parliamentary Acts from 1896 and 1897. One of the new routes connected the company’s Lesmahagow branch, about a mile north of Larkhall, with the Stonehouse branch, a distance of about 4½ miles. Opened as a single line, the structures were constructed to eventually accommodate two tracks.

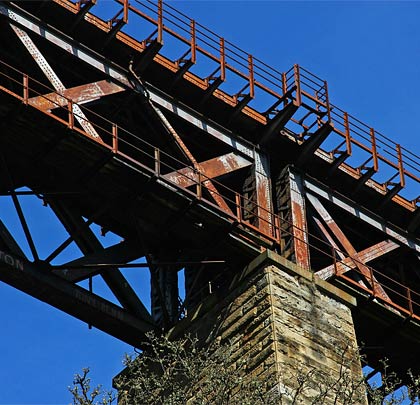

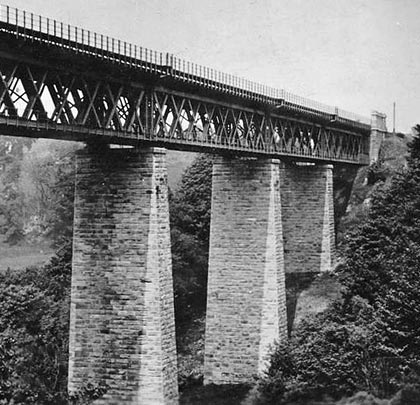

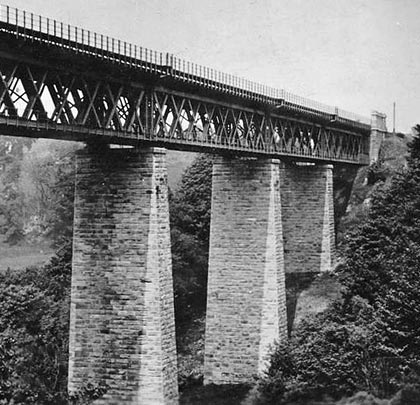

The River Avon was traversed by two outstanding viaducts. The more southerly, at Stonehouse, comprised eight equal spans of 145 feet, carrying the line for 407 yards at a height of 158 feet whilst the other, to the west of Larkhall, was shorter but more imposing, being 285 yards long and reaching 175 feet above the water. This made it the highest railway bridge in Scotland. It consists of six spans of open web steel girders supported on masonry piers, with three spans of 106ft 9in, two of 140ft 9in and one of 174ft 9in. The viaduct is straight but climbs on a gradient of 1:80. The total weight of its steelwork is 1,399 tons whilst the quantity of masonry and concrete used is 20,192 cubic yards.

All the pier foundations are on rock at depths varying from 25ft to 60ft below ground. No construction difficulties were experienced except with pier 7 where the rock was 59ft below the surface, the overlying material being saturated mud. This foundation, which is 50ft long by 36ft wide, was taken out in two sections and had to be close-timbered for the full depth and kept dry by constant pumping.

Above their foundations, the piers and abutments consist of solid stonework, built in courses ranging in thickness from 24in at the bottom to 15in under the granite girder-bearing blocks. The facing of the piers consists of squared masonry, bonded into the interior which is filled with rough rubble thoroughly grouted in cement mortar. The top four courses of each pier consist of solid ashlar. The pier tops are 11ft long and 24ft wide, with a longitudinal batter of 1:40; in the transverse section the batter is 1:24 for the piers up to 100ft in height. The stone used to build the piers was obtained from a quarry half-a-mile away whilst the girder-bearing blocks are of Norwegian granite. To assist in the piers’ erection, a timber service bridge was built at a height of 83ft above the river, on which building materials were lowered and taken forward.

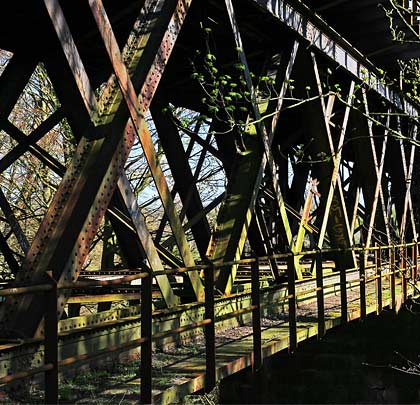

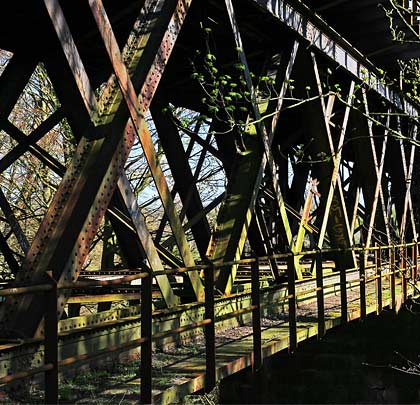

Larkhall Viaduct’s superstructure consists of main girders, cross girders and way beams; the deck is formed of buckled plates. There are two main double lattice girders for each span, placed at 16ft centres so as to be underneath the outer rails of a double track railway. For the purposes of inspection and painting, a gangway was provided on the underside of the bottom boom of one of the main girders, access to which was by ladder placed over each pier, connecting with the side platforms at rail level for the use of platelayers.

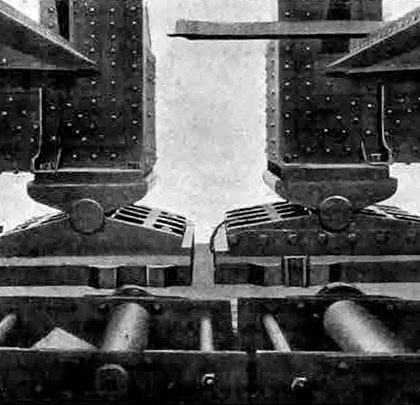

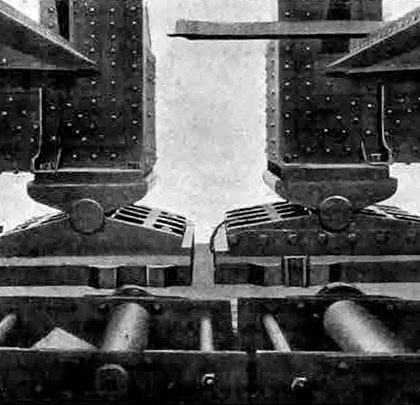

Provision was made for the expansion and contraction of the steelwork by having the lower end of each girder fixed and the other movable on cast steel bearing blocks. The bearings consist of an upper and lower portion, connected by cast steel pins, 6in in diameter. The upper portion is attached to the main girder by means of four 2in bolts, while the lower portion, in the case of the fixed end, is bolted to a cast iron sole plate. For the movable end, a sliding bearing plate of phosphor bronze was fitted into and bolted to the underside of the lower portion of the bearing block, which rests upon the top of a cast iron sole plate. To protect the phosphor bronze plate from dirt and weather, a gun metal strip was bolted to each end of the bearing block which scrapes along the upper surface of the sole plate when any movement takes place, the sides being protected by malleable iron strips.

The upper surfaces of the sole plates were machined to give a true and even bearing for the steel blocks and were fixed to the pier by four 2in rag bolts embedded in the granite bearing blocks as well as by four steel rails, 8ft 6in long, sunk into the masonry and wedged between projections on the sole plates.

Erection of the main girders started between piers 1 and 2. Two timber trestles were assembled, dividing the 102ft span into three parts and on these was built a temporary stage, consisting of steel girders 13ft deep and 10ft apart. The various members of these temporary girders were of uniform section and bolted together using ⅞in bolts. Attached to the bottom of this stage were 27ft H-beams, 14in by 6in and fixed in pairs 13ft apart. On these were placed camber blocks and the main girders built outside the temporary girder-staging by means of a crane travelling on the latter’s top booms. The granite bearing blocks, weighing 6 tons each, were permanently placed after the erecting stage had been built, having been brought forward and lowered into position using the steelwork sub-contractors crane.

To erect the main girders of the second span, also 102ft in length, the stage was built out to pier 3, after which the work was proceeded with concurrently. For the 140ft third span, the erecting stage was taken down from between the main girders of the first span and built out as before until the centre of the span had been reached. At this point a framework, consisting of two braced timbers, was attached to the underside of the erecting stage and four 1in steel ropes passed under one end of each, fastened to the end posts of the second span’s permanent girders whilst the other end, after passing over pier 4, was fixed to the base of pier 5 and kept taut using union screws. A similar approach was taken in assembling the 175ft span between piers 4 and 5.

For the 140ft span between piers 5 and 6, the southernmost half was built on timber staging supported on the ground and the other on the steel erecting stage which was built out to meet this staging from the adjoining span. The remaining 102ft span was constructed entirely on timber staging supported on the ground.

The main girders of each span were completely riveted up before any part of their erecting stage had been removed, the riveting being fulfilled, wherever possible, by pneumatic power.

The viaduct was subjected to severe tests in the spring of 1905. Twelve engines, with a combined weight of about 780 tons, were formed into one train and run over the structure at speeds up to 50mph, much higher than the branch’s linespeed. No vibration of the bridge was detected and the results were greeted with satisfaction by those in attendance.

Initially responsible for the engineering was the late George Graham, for many years engineer-in-chief of the Caledonian Railway, but it was completed under the direction of his successor, Donald A Matheson. Sir John Wolfe Barry acted as consulting engineer throughout the course of the works. The resident engineer for the viaducts was John W F Gardner. Contracted to fulfil the works was A H Boyle of Glasgow whilst the Arrol’s Bridge and Roof Company of Germiston Works, Glasgow, manufactured the steelwork.

Commercial traffic first rode the girders of Larkhall Viaduct on 1st July 1905. Stopping passenger services continued until October 1965, the line thereafter was used by trains to Auchlochan Colliery. But these ceased and the viaduct was officially taken out of service on 16th September 1968.

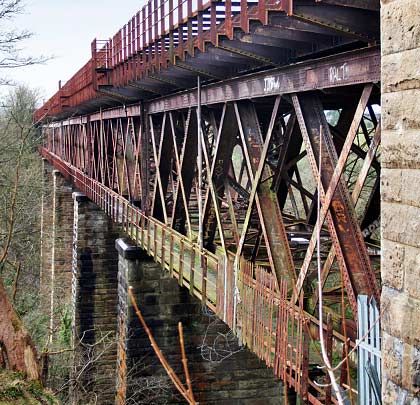

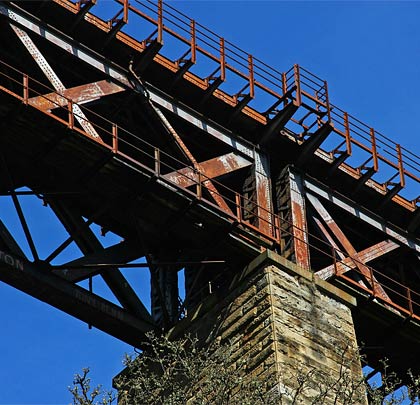

In 1984, the viaduct was sold to a property developer and permission was sought to demolish it in 1984 and 1994. This was refused on both occasions following considerable local opposition, the structure having been granted a Grade B listing in August 1985. In the mid-Nineties, a survey carried out for Clydesdale District Council deemed the bridge to be in reasonable condition, with some corrosion of the steelwork and rotting/missing timbers on the walkways. The council sought funding to incorporate the viaduct into the Avon Walkway from Strathclyde Park to Stonehouse, but this was not pursued.

In 2005, a 12-year-old schoolgirl suffered a broken back and elbow after slipping and falling from the viaduct. Five years later, following other incidents of vandalism and recklessness, listed building consent was granted for the erection of concrete walls at both ends, preventing access.

Today, whilst Larkhall Viaduct remains a significant local landmark, its condition continues to decline and it is now categorised as being at moderate risk on the Buildings at Risk register. The structure goes by several alternative names including Broomhill, Millheugh and Morgan Glen.

Click here for more of The Doofers’ pictures.